Skills and innovation

In the heart of the Alps, between fertile vineyards and eternal snow, Valais harbours a facet as unknown as it is unique: a thriving industry with cutting-edge technologies and future-oriented centres of excellence.

Twenty-five percent of the canton's added value is generated in this sector. From family-run SMEs and start-ups to large international corporations, Valais offers industrial companies an extremely economically strong terrain testifying to the canton's excellence and quality.

Food

Mineral water, dried meat, alpine herbs, sweeteners and perch fillets have one thing in common: they contribute to the fame of the food industry in Valais. Speaking of mineral water, as Switzerland's temple of water, Valais is home to Aproz Sources Minérales AG, the country's largest bottler of mineral water. This little-known knowledge complements the riches of the canton’s terroir. Such are the canton’s characteristic treasures – from the source of the Rhone to Lake Geneva.

Automotive and aviation

Jaguar, Mercedes, Land Rover or Audi: Valais know-how is enough for renowned car manufacturers. Body sheet metal, metallic paints, plastics, air conditioning systems and intelligent sensors "Made in Valais" are installed in their vehicles worldwide. And some of this expertise also finds its way into the railway and aviation sectors. Customers include big names like Stadler Rail, Siemens and Alstom; while aircraft manufacturers Airbus and Dassault also source top-quality recycled aluminium sheeting from Valais.

Wellness and Cosmetics

Known for their vineyards and sun-drenched fruit, the slopes of the mountains in Valais are also home to a multitude of herbs and medicinal plants with well-known virtues, including edelweiss, a protected plant, and arnica, a beneficial plant. These and other plants have soothing, stimulating, moisturising, antioxidant or regenerative effects in the form of skin creams, herbal teas and sweets. Sage is the leading herb in Valais, yielding 40 tonnes per year. Bild 750

Cleantech

Cleantech, so-called clean technologies, are characterised by their efficiency and environmental friendliness, among other things by using natural resources sparingly. Valais-based companies are leading the way in protecting water quality, recycling waste as a raw material or energy source, and pioneering textile processing methods. The cantons of western Switzerland have set up CleantechAlps, a joint platform to promote clean technologies. In this way, they support these companies in the development of their activities.

Energy

With its more than 45 large dams, Valais generates more than a quarter of the energy consumed in Switzerland from hydropower. With over 300 days of sunshine a year, the canton also offers ideal conditions for photovoltaic systems. Accordingly, there are several project plans for alpine solar plants. In addition to the use of water and sun, there is also wind power, the reutilisation of organic waste, so-called biomass, and wood pellets. These clean, sustainable and efficient energy sources secure the canton's energy supply.

Mechanical engineering

Thanks to its pool of ETH and HES engineers, its openness to the world and its competitiveness, Valais has attracted high-performance companies that produce innovative machinery for various sectors. These include the food, clothing and health industries. Some of them have established themselves as world leaders in their field. With a largely international clientele, most of the products manufactured in Valais are destined for export, a highly important element. According to statistics, one out of every two francs earned by Valais industry is generated by foreign trade.

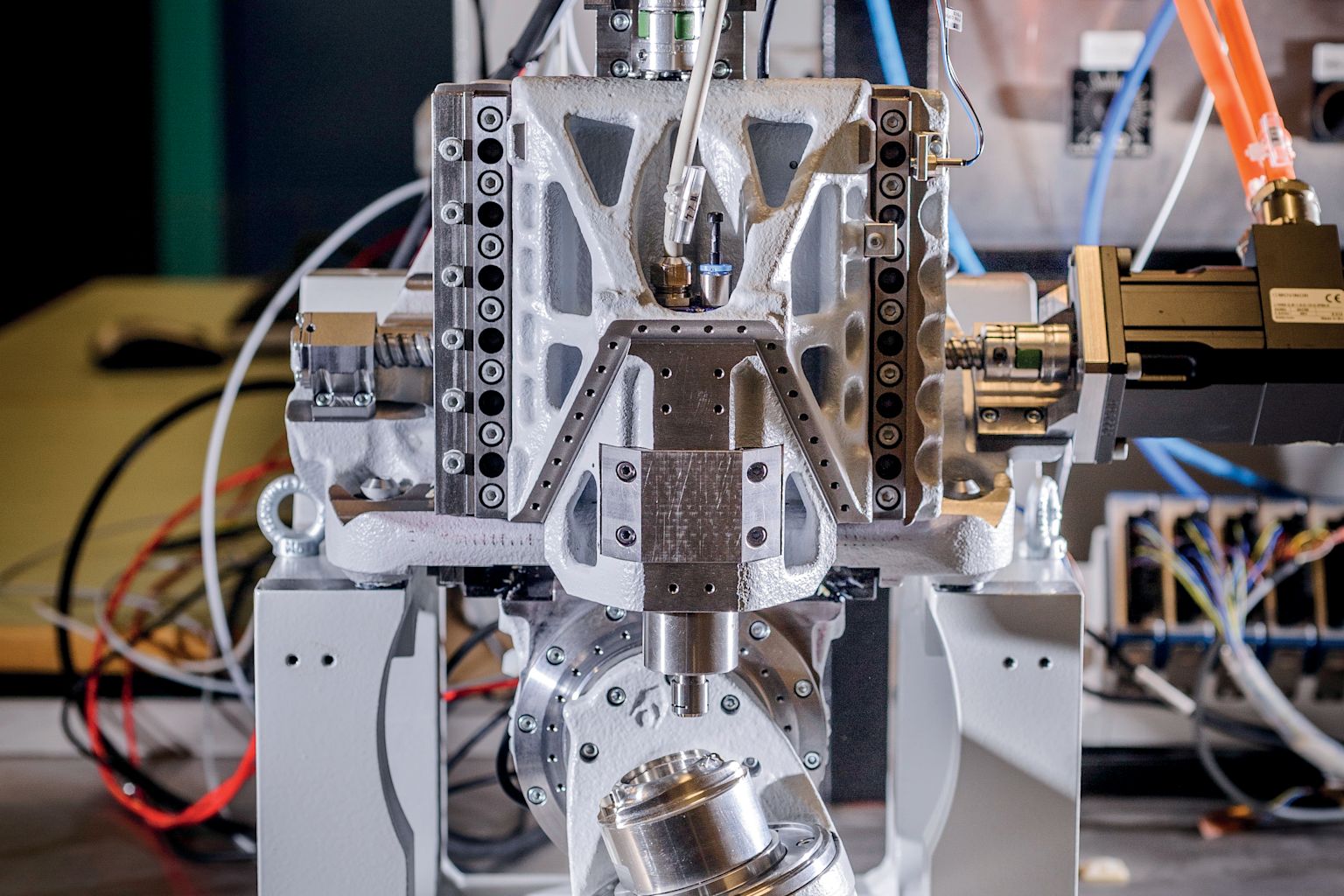

Mechanics and precision engineering

Quality and precision. Two Swiss values that are perfectly embodied by the 30 or so mechanical workshops in Valais that manufacture their own products or subcontract them. With the help of extensive and extremely powerful machinery, these companies produce components with micrometre precision as well as machines weighing several tonnes for end users and well-known customers such as CERN in Geneva. MG-Tech in Saxon, for example, also designs jewellery, often produces it as one-off and custom-made pieces.

Microtechnology

The Swiss watch industry is not limited to the valleys of the Jura. Valais also plays a significant role, thanks to innovative, creative microtechnology companies whose visionary talent, daring and discretion make them so successful. Manufacturing tiny parts such as gear wheels and springs to an accuracy of a thousandth of a millimetre, they do so with a level of quality that captivates even the biggest brands. Incidentally, one of the oldest Swiss watch brands, the West End Watch Co, is based in Leytron.

Pharmaceuticals, chemistry and biotechnology

Since the 20th century, many pharmaceutical and chemical industry companies have settled in Valais. This is mainly thanks to the cheap energy available from hydroelectric power. The pioneers of yesteryear are now large international corporations known for their outstanding excellence in the realm of chemical and pharmaceutical products, as well as civilian explosives, pyrotechnics and fine chemicals. Valais is also home to biotechnology companies that develop medicines against cancer, infectious and rare diseases as well as plant protection products.

Health and medical technology

An entrepreneurial and pioneering spirit, incubators and a university are the essential factors that make Valais a cradle of innovation. All the links in the value chain are present in the health sector. From research to the development of medical products and distribution, various Valais-based start-up companies are working on the medicine of the future. Professional athletes also benefit from this such as world champion skier Lara Gut-Behrami who has used Myotest devices from Sion for her physical preparation.

Information and communication technology

A leading location in Switzerland for information and communication technology with its own university of applied sciences, Valais has a solid network of students, researchers, developers and companies, with IT and software solutions created that are used far beyond the cantonal borders. Customers include the Swiss Federal Railways (SBB) and Swisscom. The latter has integrated speech recognition technology from KeyLemon in Martinach into its TV-Box 2.0. Speaking of which, TechnoArk in Sierre was the first centre for information technology in Switzerland.

Innovation, research and development

In addition to its idyllic landscapes and famous holiday resorts, Valais stands out for its creativity in highly focused areas. As a true centre of innovation and technology, its research institutes, its universities and its innovation park provide an ideal environment for ideas and start-ups to flourish. This solid network of partners attracts many students, researchers and traders from Switzerland and abroad. Finally, Valais has an over 25,000 sqm technology park.

Roboclette

A hallmark of Valais engineering. Roboclette is the world's first machine able to spread melted cheese. The result of a joint idea by Emmanuel Pignat, Sylvain Calinon and Nicolas Fontaine, the Idiap research institute in Martigny put the development into practice. The Roboclette also owes its success to the support of Eddy Baillifard, ambassador of Valais Raclette AOP, Valais/Wallis Promotion and Workshop 4.0. Between tradition and innovation, this technical gem illustrates the potential of Valais research in the field of artificial intelligence.